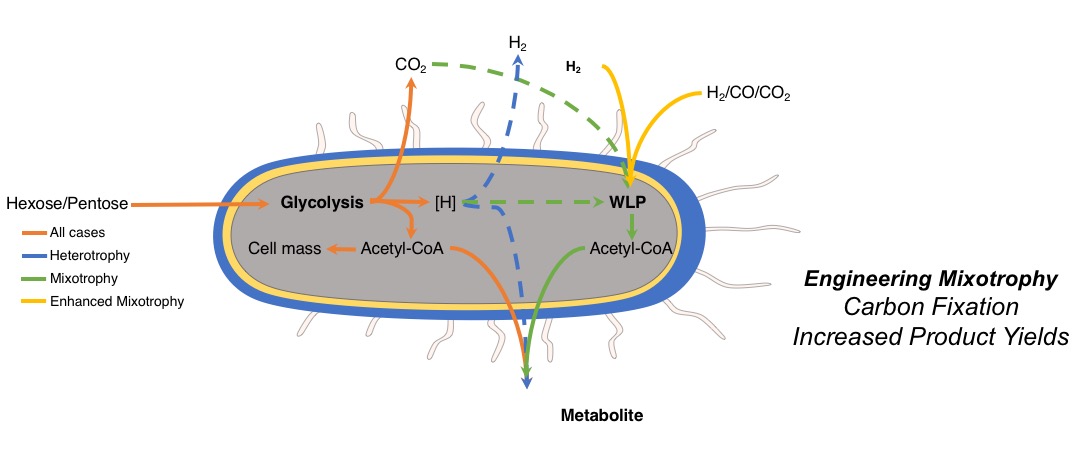

Atmospheric CO2 concentrations have increased significantly in recent years due to human activities leading to a substantial threat to our climate on earth. The demand for energy is steadily growing, and despite the current low oil prices the stockpiles of petroleum reserves are quickly being depleted. Renewable transportation fuels generated from waste gases hold large promise in reducing greenhouse gases such as CO2 . As a result, new technologies capable of utilizing low value feedstocks and waste gasses, such as H2, CO and CO2, must be developed to meet our growing need for liquid fuels. One potential renewable fuel is the microbial fermentation product biobutanol. Biobutanol has many advantages over other potential fuels as it is compatible with our current transportation fuel infrastructure, has a high energy density and is immiscible with water. Currently, traditional fermentations employing carbohydrate substrates to produce butanol and other reduced products are limited by the decarboxylation reactions occurring during glycolysis. As a result, only a maximum of two-thirds of the carbon contained in the feedstock can be recovered in fermentation products. The other third of the feedstock is lost as undesirable CO2 . In order to increase butanol yield, we propose to re-assimilate the evolved CO2 via the Wood-Ljungdahl pathway (WLP). In addition, exogenous CO2, CO and H2 added to the fermentation provides an additional cheap and abundant feedstock. Employing this concept of mixotrophy can increase either native, already existent pathways for microbial product production (for example those of C. acetobutylicum) or enhance non-native, synthetic pathways for the production of fuels and chemicals.

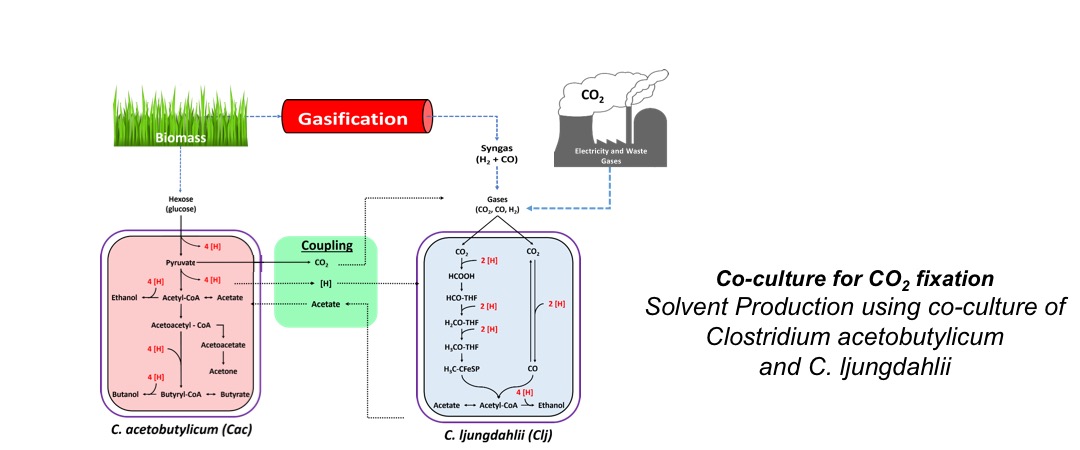

Solvent Production Using a CO2 – Fixing, Synthetic, and Syntrophic Clostridium Co-culture

In nature, most organism live in microbial consortia, where the metabolic burden is divided among multiple organism to produce the molecules necessary for survival. A co-culture of C. acetobutylicum and C. ljungdahlii can provide superior carbon yields due to the sequestration of the CO2 and H2 waste released by C. acetobutylicum. Solventogenic Clostridium acetobutylicum can utilize a wide variety of sugar substrates, such as molasses, starch, and hemicellulose (a major component of biomass) to produce acetone, butanol and ethanol, in a process known as the ABE fermentation. In a co-culture system, C. ljungdahlii produces additional acetate by consuming CO2 and H2 waste released by C. acetobutylicum. At the same time, C. acetobutylicum consumes the additional acetate to produce additional solvents i.e. ethanol and butanol. Overall, the co-culture system is capable of consuming a mixed feed of sugars and inorganic gases, in order to completely utilize the carbon available in the sugar substrate to produce improved solvent titers.

Selected Publications:

Acetogenic mixotrophy: novel options for yield improvement in biofuels and biochemicals production

AG Fast, ED Schmidt, SW Jones, BP Tracy

Current opinion in biotechnology 33, 60-72. 2015.

Stoichiometric and energetic analyses of non-photosynthetic CO 2-fixation pathways to support synthetic biology strategies for production of fuels and chemicals.

AG Fast, ET Papoutsakis

Current Opinion in Chemical Engineering 1 (4), 380-395. 2012.